WHO WE ARE

MST Rail, a German company, develops & manufactures innovative technology for the concrete sleeper industry.WHAT WE DO

MST Rail Africa offers a solution that beats the challenges of conventional stationary sleeper production.WHY CHOOSE US?

Our advanced technology allows to scale up capacity and has significant financial advantages.MOBILE SLEEPER TECHNOLOGY

GENERAL

With our mobile factory you manufacture concrete sleepers at your project sites. Thus, it does significantly reduce the costs per concrete sleeper, does create jobs hence it does increase your value added.Due to the technology developed by us, we enable you to adjust your investment to the capacity you need for your current and future projects. In addition, our technology enables you to meet different product requirements for different projects by simply changing the setup. With our technology you will be able to produce different types of sleepers by changing the concrete shells in the frame.

Of course, we design and manufacture all necessary changes to the setup of your mobile factory so that you can always meet the requirements of your customer. The following simulation shows the procedure of manufacturing, please contact us for further details and discussion about your project needs.

CAPACITY

The capacity of a standard factory setup is about 20 to 24 concrete sleepers per hour which adds up in a 9-hour shift to about 200 sleepers per working shift.

With 2 shifts per day and 24 working days per month, you will produce about 9600 sleepers per month. This equals to an annual capacity of 100,000 sleepers.

Please speak to us about the requirements for your project.

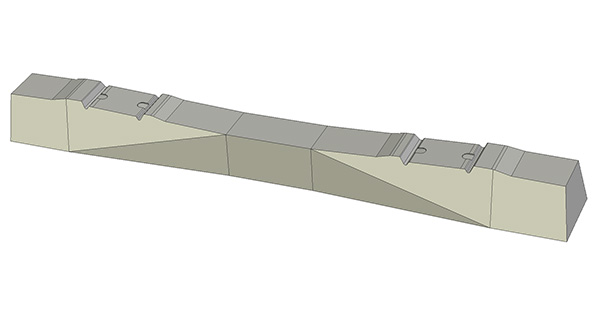

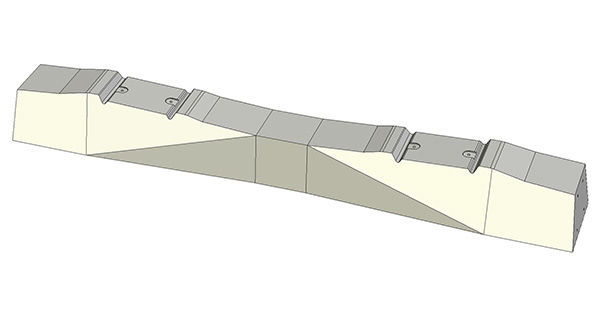

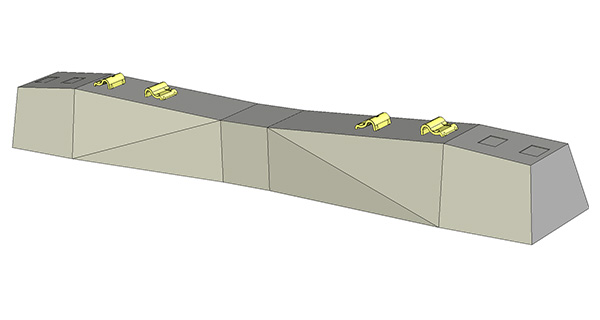

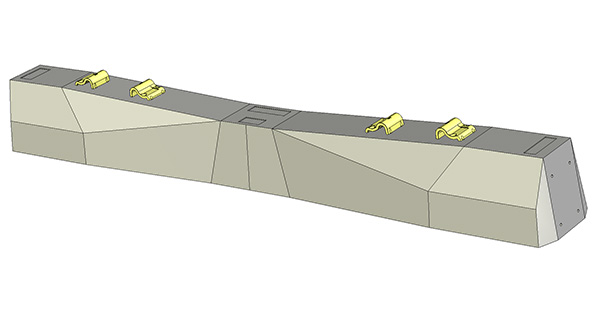

B70 W-Fastening 1435mm

PY W-Fastening 1065mm

PY P-Fastening 1065mm

P2 P-Fastening 1065mm

ADDITIONAL SUPPLY

In addition to the factory, we also supply the following but not limited to:- Concrete laboratory including

- Concrete sleepers bending test machine

- Test equipment for sleeper measurements

- Batching Plant including Cement Silo

- Office container

- Workshop container

- Dome shelter between two containers

- Generator 3 phase 60kVA

- Forklift 5t for sleeper and mould transport

- Loader for the batching plant

ADVANTAGES

FINANCIAL ADVANTAGES

For about a quarter of the usual investment for a stationary factory, you buy a modern mobile factory for production of concrete sleepers according to EU standards.For you it means a significantly lower risk of your investment because after the end of the project you take the factory to the next project and set it up in a different area even in a different country if required.

In case the capacity of your factory is not adequate for the new project, you can expand your factory with little financial effort. Of course, you can also set up a second factory at the same place and make use of synergy effects, think about the laboratory and the concrete mixing plant.

With your MST Rail mobile factory, you create added value for your company and for the community in the area in which you manufacture the sleepers because you use local resources like the concrete aggregates, human resource and all the other stuff you need. For your company and the community, you create in this way independence from foreign companies that take the added value out of your country.

MANUFACTURING ADVANTAGES

For you and your customer the greatest advantages of our mobile technology are the tremendous savings in transport compared to the costs for transport of concrete sleepers from a stationary factory, which are often far away from the project site.Along with this, you reduce the logistical effort to a great extent. Remember, you need about 1450 concrete sleepers for one kilometre of railway. Due to the heavy weight of a concrete sleeper, around 14 truck loads are required per km railway line.

Another big advantage of the production with our mobile factory is often not immediately been seen.

Because you already know at the beginning of your project how many sleepers in what time period you must produce you have got the advantage to plan the production schedule accordingly.

Thus, you plan how many sleepers your people produce per week, month or until a certain deadline. You do not need to pay for a huge material stock, human resource but also for a stock yard for the sleepers itself.

Regarding the material, you plan with your suppliers for the entire project regarding quantity, delivery intervals and finally the price.

OUR SERVICES

MST Rail Africa offers you a solution that beats the challenges of conventional stationary sleeper production to your benefit.

Our innovative technology has been developed for you and your projects in Africa with a focus on quality and sustainability. Our interdisciplinary and independent engineering team developed and designed the technology according to your requirements and prospects.

We also offer comprehensive technical support for your railway projects not only limited to railway sleepers.

The following is our range of services:

Our innovative technology has been developed for you and your projects in Africa with a focus on quality and sustainability. Our interdisciplinary and independent engineering team developed and designed the technology according to your requirements and prospects.

We also offer comprehensive technical support for your railway projects not only limited to railway sleepers.

The following is our range of services:

MOBILE FACTORY

manufactured & supplied to Customers & projects all over Africa- Tailor made to the needs of the client

- Laboratory for concrete & sleepers

- Mobile concrete batching plant

ENGINEERING

supplied from South Africa into Africa- Training & Skills Development

- Maintenance & Calibration

- Sleeper Design Calculation

MATERIAL SUPPLY

from Africa, EU, China etc. into Africa- Pre-Tension Steel

- Rail Fastening

- High Strength Cement

SLEEPER MANUFACTURING

on behalf of our client for different projects all over Africa- Advanced technology

- Adhere to the highest standards

- Meets customer requirements

ABOUT US

MST Rail GmbH, a German company, develops and manufactures innovative technology for the concrete sleeper industry. The idea and application of a mobile factory to produce pre-stressed concrete sleepers at the project site is unique worldwide and only available from MST Rail.

MST Rail GmbH founded MST RAIL AFRICA in Gaborone, Botswana, in order to work with EU and African partners with the common goal of producing, selling and operating the mobile sleeper factories in Africa. With our technology we offer countries and railway companies the opportunity to reduce the costs for construction of new railway lines as well as the life cycle costs during the maintenance phase.

The production of our technology in Africa creates jobs in many different areas. Almost all these jobs require advanced and specialized knowledge and skills, which require training and further skills development of the employees.

The employment of our mobile technology guarantees the use of local resources and, most important, creation of local jobs in many different areas in the country. Special knowledge and skills are required for production of concrete sleepers, which is why we work with our experienced team from MST Rail Africa together with the local team until they will be able to run the factory on their own.

MST Rail GmbH founded MST RAIL AFRICA in Gaborone, Botswana, in order to work with EU and African partners with the common goal of producing, selling and operating the mobile sleeper factories in Africa. With our technology we offer countries and railway companies the opportunity to reduce the costs for construction of new railway lines as well as the life cycle costs during the maintenance phase.

The production of our technology in Africa creates jobs in many different areas. Almost all these jobs require advanced and specialized knowledge and skills, which require training and further skills development of the employees.

The employment of our mobile technology guarantees the use of local resources and, most important, creation of local jobs in many different areas in the country. Special knowledge and skills are required for production of concrete sleepers, which is why we work with our experienced team from MST Rail Africa together with the local team until they will be able to run the factory on their own.

CONTACT US

EUROPE: HEAD OFFICE

- Frankfurt/Main - Bad Soden

Ralf Sobottka

Martin Voss

Malekantwa Mmapatsi

- AFRICA: REGIONAL OFFICE

Gaborone, Botswana

(Will be opened soon)

Martin Voss

- AFRICA: TECH & SERVICE

Johannesburg, South Africa